Introduction: In the realm of material recovery and recycling, the quest for efficient and sustainable solutions is perpetual. Among the array of technologies available, Eddy Current Separators (ECS) stand out as a remarkable tool for non-ferrous metal recovery. Harnessing the power of eddy currents, these separators are revolutionizing the way we approach material separation and resource conservation.

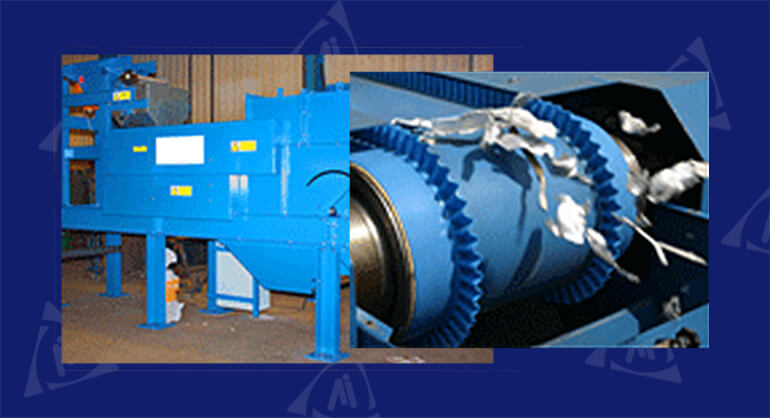

Understanding Eddy Current Separators: At the heart of an Eddy Current Separator lies a rapidly rotating magnetic rotor. This rotor creates a powerful magnetic field, inducing eddy currents in conductive non-ferrous metals such as aluminum, copper, and brass. These eddy currents generate an opposing magnetic field, repelling the metals away from the conveyor belt carrying the material. This forceful repulsion propels the non-ferrous metals out of the material stream, allowing for their separate collection and recycling.

Applications and Benefits: Eddy Current Separators find wide applications across various industries:

- Recycling Industry: ECS are extensively used in recycling facilities to separate aluminum cans, copper wires, and other non-ferrous metals from municipal solid waste, electronic scrap, and automotive shredder residue.

- Resource Recovery: In mining operations, ECS are employed to recover valuable metals from slag, enhancing resource recovery and reducing waste.

- Plastic Recycling: ECS play a crucial role in plastic recycling by removing non-ferrous metals from shredded plastic, ensuring purity and quality of the recycled material.

The benefits of Eddy Current Separators are manifold:

- Efficiency: ECS can achieve high separation efficiency, even with fine particles, ensuring maximum recovery of valuable metals.

- Eco-Friendly: By facilitating the recycling of non-ferrous metals, ECS contribute to environmental sustainability and resource conservation.

- Cost-Effectiveness: The recovered metals can be sold or reused, providing a cost-effective solution for material recovery.

- Versatility: ECS can be customized to suit different applications and material types, making them highly versatile in various industries.

Challenges and Future Prospects: While Eddy Current Separators offer numerous advantages, challenges such as the need for regular maintenance and adjustments exist. However, advancements in technology are addressing these challenges, with innovations such as automated controls and improved rotor designs enhancing the efficiency and reliability of ECS.

In conclusion, Eddy Current Separators represent a significant advancement in material recovery technology. Their ability to efficiently separate non-ferrous metals from waste streams is crucial for sustainable resource management. As technology continues to evolve, ECS are poised to play an increasingly vital role in the circular economy, driving the shift towards a more sustainable and efficient approach to material recovery.